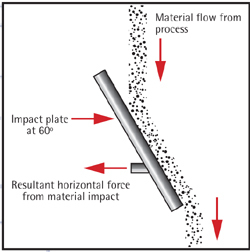

IMPACT WEIGHERS work by measuring the horizontal force only from a free falling product hitting an impact plate. This horizontal force has a direct relationship to the material flowrate. The force can be measured by a loadcell or LVDT, directly connected to the impact plate. This force is integrated with respect to time to give a mass flowrate and totalisation. By measuring only the horizontal force any product build up on the impact plate does not affect accuracy. Impact weighers are particularly suited to applications where there is a vertical flow stream and conventional belt scales or weighfeeders cannot be incorporated. They can be used to control a variety of prefeed devices such as screw conveyors, rotary valves and air slides. They can be supplied with their own dust tight housing or made to fit into existing steelwork and chutes. An advantage of using an Impact Weigher is that the product can still be totally enclosed from the environment.

ENDRESS AND HAUSER IMPACT WEIGHERS

LEEweigh can support old Endress and Hauser Impact Weighers models DE10 and DE20 for:

Sales

Service

Commissioning

Spares

Calibration